The biopharma industries increasingly rely on Contract Development and Manufacturing Organizations to accelerate drug development, reduce costs, and navigate complex regulatory environments. Choosing the best CDMO company is a strategic decision that impacts the success of a project at every stage, from early development to commercial manufacturing. However, not all CDMO companies are equal. The right CDMO partner must align with a company’s technical, regulatory, and business objectives, ensuring efficiency, compliance, and high-quality production.

What is a CDMO and Why Does Your Business Need One?

CDMOs serve as essential partners for pharmaceutical companies, offering expertise in process development, manufacturing, and regulatory compliance. In a rapidly evolving industry where time-to-market is a critical differentiator, outsourcing some activities to an external service provider allows businesses to focus on innovation while leveraging the advanced capabilities of specialized manufacturing partners. European end-to-end companies, in particular, provide fully integrated services, ensuring seamless transitions between drug development stages while maintaining stringent quality control and regulatory compliance [1, 2].

Beyond drug manufacturing, CDMO services extend to process development, formulation, packaging, and supply chain management. As regulations become more rigorous, particularly in the United States and Europe, partnering with an experienced CDMO company ensures compliance with GMP standards, reducing the risk of costly delays or failed regulatory approvals. Given the stringent requirements set by the EMA, FDA, and other global regulatory agencies, choosing a CDMO with a history of successful track record of regulatory submissions/approvals and GMP, GCP, GLP, and ISO certification is non-negotiable [3-5]. Choosing a CDMO is not just about production capacity – it’s about securing a strategic partner that can optimize processes, reduce costs, and support a company’s long-term growth.

Key Factors to Consider When Choosing a CDMO Company

One of the most critical CDMO selection criteria is the ability to provide comprehensive services. An end-to-end CDMO company eliminates the need to work with multiple vendors, reducing the complexity and risks associated with process transfers, quality inconsistencies, and supply chain disruptions. Companies that choose an integrated CDMO partner benefit from streamlined communication, a unified regulatory strategy, and a more efficient path from drug development to commercialization. This approach is particularly beneficial in Large Molecules manufacturing, where maintaining process control and batch consistency is crucial [6].

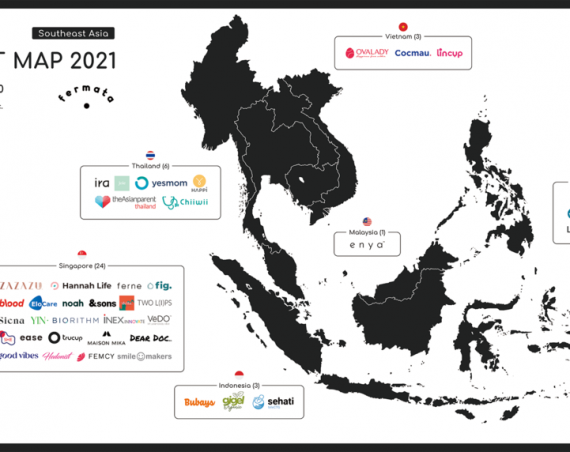

There are many considerations to take into account when looking for the proper business partner. Geographic location is a critical yet often overlooked factor in selecting a CDMO company, impacting regulatory compliance, cost-effectiveness, supply chain stability, and long-term business success [7]. European end-to-end CDMO companies, particularly those in Central and Eastern Europe (CEE), provide world-class manufacturing at significantly lower costs than their Western European or North American counterparts, reducing operational expenses without compromising quality [4].

In an increasingly competitive market, the decision to work with a CDMO pharma partner is also a financial one. Outsourcing drug substance manufacturing eliminates the need for major capital investments in facilities, equipment, and personnel, making it a cost-effective solution for both emerging biotech startups and established big pharmas. The ability to scaleup rapidly, meet evolving market demands, and leverage expertise in risk management makes biopharma outsourcing a necessity rather than an option.

A Common Pitfalls to Avoid in CDMO Partner Selection

Many pharma companies remain dissatisfied with the quality of their business partnerships because they did not conduct sufficient vetting at the selection stage. Not all CDMOs have the same capabilities. Failing to match the CDMO’s experience with the specific needs of projects can lead to inefficiencies and poor results [8]. Therefore, when selecting a partner to work with, it is important to consider several aspects and focus on detecting potential warning signs. Among the most important are:

- Selecting a CDMO Without Long-Term Scalability

- Poor Project Management and Communication

- Prioritizing Cost Over Quality and Expertise

- Skipping an On-Site Audit or Facility Visit

- Overestimating a CDMO’s Adaptability

- Downplaying End-to-End Capabilities

- Failing to Assess Regulatory History

- Ignoring Supply Chain Security

Avoiding these pitfalls helps biopharma companies secure a reliable, compliant, and technically proficient CDMO partner that supports long-term success.

Building Strong CDMO Partnerships for Your Project

Building a robust partnership with a CDMO is pivotal for the successful development and commercialization of therapeutics. Trustful communication plays a critical role in maintaining alignment throughout the partnership. Early engagement in the drug development lifecycle allows for comprehensive alignment on project goals, timelines, and regulatory strategies, ensuring that both parties are synchronized from the outset. Clearly defining the scope of work is another critical factor; it enables the CDMO to allocate appropriate resources and expertise, facilitating efficient project execution. Many companies struggle with outsourcing because of misaligned priorities or unclear deliverables. To avoid this, both the biopharma company and the CDMO must establish structured governance models, conduct regular progress reviews, and maintain transparency in decision-making. Setting clear timelines, risk management strategies, and escalation procedures ensures that potential challenges are addressed before they disrupt the project.

Moreover, a well-crafted Request for Proposal that outlines specific project requirements and expectations can aid in selecting a CDMO whose capabilities closely match your project’s needs. Regular communication and transparency throughout the partnership foster trust and collaboration, allowing for proactive identification and mitigation of potential challenges. Digital project management tools and real-time data-sharing platforms can enhance understanding between technical, regulatory, and business teams. My experience shows that omitting clear communication significantly hinders cooperation at every stage of the project.

References

- Silva D, Chrobok M, Ahlén G, Blomberg P, Sällberg M, Pasetto A. ATMP development and pre-GMP environment in academia: a safety net for early cell and gene therapy development and manufacturing. Immunooncol Technol. 2022; 16: 100099.

- Elekidis A, Georgiadis M. Optimal contract selection for contract manufacturing organizations in the secondary pharmaceutical industry. Comput Chem Eng, 2022; 165: 107957.

- US Food and Drug Administration, Contract Manufacturing Arrangements for Drugs: Quality Agreements Guidance for Industry Guidance for Industry, 2016.

- Florio M, Pancotti C, Procházka D. European pharmaceutical research and development. Could public infrastructure overcome market failures? European Union, European Parliamentary Research Service, Scientific Foresight Unit, 2021.

- Bedford P, Jy J, Collins L, Keizer S. Considering Cell Therapy Product “Good Manufacturing Practice” Status. Front Med (Lausanne). 2018; 5: 118.

- Strategic Antibody Outsourcing: Guidance On Selection, Services, And Facility Fit, Outsourced Pharma, 2024.

- Moosivand A, Rangchian M, Zarei L, Peiravian F, Mehralian G, Sharifnia H. An application of multi-criteria decision-making approach to sustainable drug shortages management: evidence from a developing country. J Pharm Health Care Sci. 2021; 7: 14.

- Four Steps To Identifying The CDMO Proposal Worth Signing, Outsourced Pharma, 2024.